Every well’s success depends on the precision of its completion phase, the bridge between drilling and production. Choosing the right oil well completion tools ensures optimal flow, zonal isolation, and reservoir control while reducing downtime and maximizing output.

In today’s dynamic energy landscape, downhole completion tools must deliver reliability under high temperature, high pressure, and corrosive conditions. Yet with so many completion tools companies offering varied designs and technologies, selecting the right tools requires more than brand familiarity; it demands technical insight.

This blog explores the key factors that influence tool selection and breaks down the top 10 completion tools oil and gas professionals trust most. Whether you are optimizing production, improving safety, or planning your next completion operation, this guide will help you make informed, performance-driven decisions.

Factors Influencing the Choice of Completion Tools

Selecting the right completion tools begins with a deep understanding of the well’s design, objectives, and environmental challenges. Each well presents unique variables, and the effectiveness of downhole completion tools depends on how accurately they are matched to these parameters. A well-informed selection minimizes operational risks, optimizes production, and ensures long-term tool reliability.

1. Wellbore Geometry and Zonal Profile

Wells vary widely in diameter, deviation angle, and completion design. Properly sizing and configuring oil well completion tools to the casing diameter and annular space ensures correct placement and sealing integrity. The geometry also dictates tool choice for multizone completions or deviated wells, where precise alignment affects flow efficiency and tool lifespan.

2. Reservoir Conditions and Pressure Requirements

Reservoir depth, formation pressure, and temperature are decisive factors in tool selection. Wells operating under high temperature or high pressure (HPHT) conditions require completion tools oil and gas built with premium alloys, reinforced elastomers, and pressure-tested seals. These materials prevent deformation, corrosion, and mechanical failure during critical stages like packer setting or fluid injection.

3. Fluid Properties and Chemical Compatibility

Completion tools must be compatible with reservoir fluids such as brine, crude oil, gas, and drilling muds. Poor chemical compatibility can cause swelling, corrosion, or surface degradation, compromising tool performance. Choosing downhole completion tools designed to resist acids, H₂S, and CO₂ exposure ensures durability and sustained operation across multiple well cycles.

4. Logistics, Service Support, and Vendor Reliability

Even the best tools underperform without dependable delivery and on-site technical assistance. Partnering with established completion tools companies guarantees proper installation, inspection, and after-sales support. Efficient logistics, quality certification, and API-compliant testing are equally vital to prevent project delays and maintain operational integrity.

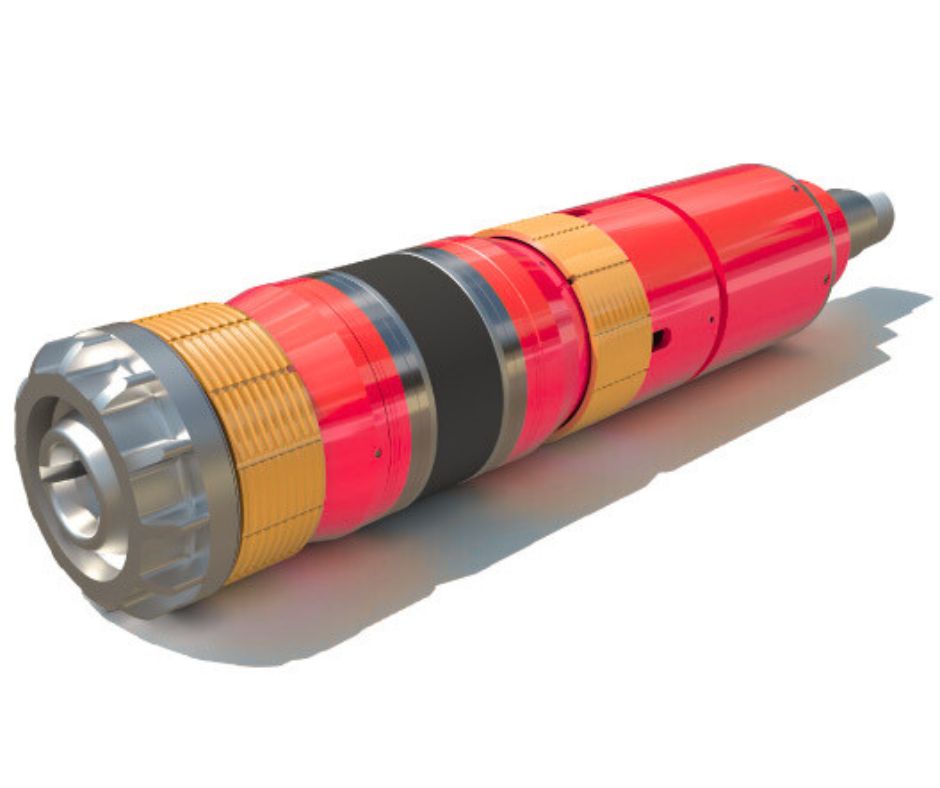

Top 10 Oil Well Completion Tools Every Engineer Should Know

Selecting the right downhole completion tools is crucial to the success of every oil and gas operation. Each component serves a unique function, from zonal isolation to controlled cementing, ensuring safe and efficient production. Below are ten essential completion tools oil and gas operators rely on to optimize performance, maintain integrity, and streamline operations.

1. Bridge Plug

The Bridge Plug is a dependable downhole barrier designed for well isolation, abandonment, fracturing, and squeeze cementing operations. Manufactured from cast iron and rated for pressures up to 10,000 psi and 350°F, it ensures superior sealing across various casing grades, including P-110. This tool stands out in oil well completion tools for its drillable design, which allows for rapid retrieval and removal after service.

Its one-piece slip system guarantees firm anchoring during setting, while top-set shear stud activation enhances operational control. For HPHT wells, elastomer options like HNBR, Viton, or Aflas provide exceptional resistance against heat and chemical degradation, reinforcing its reliability in harsh drilling environments.

Key Features

- Pressure rating up to 10,000 psi and temperature up to 350°F.

- Cast iron drillable construction for efficient removal.

- One-piece slips ensure a firm setting.

- Top-set mechanism with shear stud control.

- Available with HNBR, Viton, or Aflas for HPHT wells.

2. Hydro-Mechanical Bridge Plug

The Hydro-Mechanical Bridge Plug is a retrievable, pressure-activated isolation device ideal for temporary or long-term wellbore sealing. Its compact, durable design performs exceptionally well in deviated or high-angle wells, providing reliable zonal isolation even under extreme conditions. As one of the most trusted completion tools oil and gas specialists use, it ensures maximum safety and performance consistency.

Equipped with full-circle slips that minimize casing wear, this plug features anti-extrusion rings that protect sealing elements from deformation. It can be released using shear or right-hand rotation and is constructed from drillable materials for efficient post-operation cleanup.

Key Features

- Compact structure suitable for high-angle wells.

- Full-circle slips reduce casing wear.

- Anti-extrusion rings enhance seal durability.

- Multiple release options (shear or right-hand rotation).

- Drillable design for easy retrieval.

3. Composite Bridge Plug (CBP)

The Composite Bridge Plug is a lightweight, high-strength tool crafted from nonmetallic materials for temporary isolation in multistage and plug-and-perf completions. Favored by completion tools companies, its composition allows a rapid drill-out time, often under 30 minutes, without compromising pressure containment capabilities.

It delivers dependable performance in HPHT wells with positive sealing under high differential pressures. Its universal sleeve design supports adaptability to multiple setting tools, whether deployed by wireline or coiled tubing, making it a versatile solution for complex well operations.

Key Features

- Consistent 30-minute drill-out capability.

- Suitable for wireline and coiled tubing deployment.

- High differential pressure performance.

- Positive sealing integrity in HPHT environments.

- Compatible with universal setting sleeves.

4. Mechanical Setting Tool (MST)

The Mechanical Setting Tool offers precision control in deploying bridge plugs and cement retainers. It allows a single run for both setting and squeeze cementing, minimizing time and operational risk. Its retractable slips stay protected during run-in to prevent casing damage, making it a staple among advanced downhole completion tools.

Its pre-set slip protection design reduces tool damage, while shear-pinned safety ensures controlled activation. MSTs are compatible with a wide range of plug systems, offering flexible use across multiple completions and cementing applications.

Key Features

- Single-run operation for setting and squeeze cementing.

- Retractable slips prevent run-in damage.

- Pre-set slip protection enhances longevity.

- Shear-pinned activation ensures control and safety.

- Compatible with other cementing and plug equipment.

5. Hydraulic Setting Tool

Engineered for high-performance completions, the Hydraulic Setting Tool is designed for precision placement of packers and plugs using hydraulic pressure. It is especially valuable for offshore and deviated well applications where mechanical deployment can be challenging. This tool is a vital part of any completion tools oil and gas kit for its reliability under dynamic field conditions.

The tool enables circulation prior to setting, ensuring debris-free zones and improved cement bonding. It accepts wireline adapter kits and provides a clean, tension-based release. Its ability to perform in high-pressure, high-angle deployments enhances its use in demanding deepwater and extended-reach wells.

Key Features

- Compatible with wireline adapter kits.

- Allows circulation before packer setting.

- Ensures effective placement in deviated wells.

- Operates reliably under high pressure and temperature.

- Clean release using tubing tension or shear action.

6. Wireline Adapter Kit (WLAK)

The Wireline Adapter Kit connects downhole completion tools such as bridge plugs and cement retainers to wireline pressure setting assemblies. This adaptable system simplifies tool deployment and retrieval by offering secure, quick-attach connections suitable for both wireline and hydraulic settings. Known for its operational flexibility, the WLAK plays a critical role in efficient well completions.

It automatically disconnects from the bridge plug during the setting process, allowing immediate retrieval and preparation for reuse. With its high annular clearance and robust component locking mechanism, it guarantees reliability under pressure while maintaining tool integrity throughout the operation.

Key Features

- Compatible with wireline pressure setting assemblies.

- Adjustable subs for flexible configurations.

- High annular clearance minimizes operational restrictions.

- Secure component locking for safe performance.

- Automatic disconnection during plug setting.

7. Service Packer (RTTS)

The Service Packer (RTTS) is a bi-directional, full-bore packer used for cementing, stimulation, and production testing. It features hydraulically actuated hold-down slips that engage from pressure differentials below the element, making it an essential asset in completion tools for oil and gas operations that demand precision and reliability under extreme well conditions.

Designed for deep and high-pressure wells, the RTTS packer prevents solids or cement intrusion into the slip system. Its resettable design allows multiple operations without removal, while rotational locks and backup rings improve seal integrity at elevated temperatures and pressures.

Key Features

- Hydraulic upper hold-down slips for strong engagement.

- Backup rings on all O-rings for enhanced sealing at HPHT.

- Positive rotational locks prevent mechanical failure.

- Configurable for left-hand or right-hand set.

- Extra-long top and bottom subs for easy tong handling.

8. Mechanical Set Retrievable Bridge Plug

The Mechanical Set Retrievable Bridge Plug provides dependable zonal isolation during high-pressure cementing, acidizing, or well testing operations. Its design allows setting in both tension and compression, making it suitable for deep HPHT wells or shallow unsupported casing environments. This versatility places it among the most valued oil well completion tools in modern use.

A large internal bypass minimizes swabbing during run-in or retrieval, while its automatic bypass wash system clears debris before unsetting. These design features not only protect casing integrity but also ensure smoother plug recovery and efficient transition between well operations.

Key Features

- A large internal bypass reduces swabbing during operation.

- The bypass wash system removes debris before unsetting.

- Suitable for high-pressure and HPHT wells.

- Can be set in tension or compression.

- Ideal for both shallow and deep well isolation.

9. Spring Loaded Retrieving Tool

The Spring Loaded Retrieving Tool is engineered for the safe recovery of mechanical set retrievable bridge plugs. Its precision engagement system allows controlled release and reattachment, ensuring secure operation during plug retrieval. Among completion tools companies, this tool is valued for its ability to perform under complex downhole conditions where reliability is critical.

It features left-hand release as standard, with right-hand optional, and includes spring-loaded J-pins that prevent premature release. Its mill-tooth shoe design aids in plug recovery, making it particularly useful in wells with residual debris or irregular casing surfaces.

Key Features

- Left-hand standard release with right-hand option.

- Spring-loaded J-pins prevent accidental release.

- Mill-tooth shoes improve plug recovery in tough wells.

- Straight set-down for easy re-engagement.

- Multiple connection options to fit casing specifications.

10. Hydraulic Stage Cementing Collar

The Hydraulic Stage Cementing Collar enables two-stage cementing through a hydraulically activated sleeve, offering precise control for fluid placement. Its slim-hole profile is ideal for tight annular spaces, making it a cornerstone in downhole completion tools used for liner and cased-hole applications alike.

This collar ensures accurate cement distribution and maintains isolation between stages for consistent results. Its PDC-drillable sleeve materials simplify post-job cleanup, while field-adjustable opening pressures enhance operational flexibility. The dual-sleeve mechanism provides reliable isolation and sequential cementing without compromising structural integrity.

Key Features

- Field-adjustable hydraulic opening pressure.

- PDC-drillable sleeve for easy post-operation removal.

- Compatible with liner and cased-hole setups.

- Dual-sleeve internal activation ensures precision.

- Maintains strong isolation during stage transitions.

Precision Tools for Reliable Well Completions

The success of oil and gas operations depends on the right downhole completion tools that ensure efficiency, safety, and precision. From bridge plugs to packers, each component plays a critical role in managing pressure, isolating zones, and maintaining production flow.

AZM Oilfield is a global manufacturer and supplier of high-quality oil well completion tools and completion tools oil and gas solutions. With advanced manufacturing facilities, API-certified quality, and worldwide logistics, AZM guarantees reliability across drilling environments. Get in touch with AZM Oilfield to equip your next project with world-class completion tools.

Completion tools oil and gas are specialized equipment used to prepare a drilled well for safe and efficient production. These include downhole completion tools like packers, bridge plugs, and cementing collars.

Downhole completion tools are deployed into the wellbore to perform key functions such as isolation, pressure control, and fluid management. Examples include setting tools, retrievable plugs, and packers. AZM Oilfield provides advanced downhole tools that ensure smooth and reliable well operations.

The main components of oil well completion tools include tubing, packers, flow control devices, perforating guns, and safety valves. Together, they maintain well integrity and enable efficient hydrocarbon production.

The three main types are open hole, cased hole, and liner completion. Each approach determines how completion tools companies select and configure equipment to achieve maximum reservoir performance and operational safety.